MAINTENANCE KIT FOR TRAWLEYE

If the connectors on the TrawlEye battery and charger are not kept clean and lubricated there will be leakages and build-up of contaminants on the connectors. This will create an electrical circuit when the TrawlEye is submerged in seawater and a corrosion process will start. Low pressure on the O-ring sealing will also cause leakage and corrosion, eventually leading to defective connectors.

If the connectors on the TrawlEye battery and charger are not kept clean and lubricated there will be leakages and build-up of contaminants on the connectors. This will create an electrical circuit when the TrawlEye is submerged in seawater and a corrosion process will start. Low pressure on the O-ring sealing will also cause leakage and corrosion, eventually leading to defective connectors.

We therefore strongly recommend using our maintenance kit for weekly maintenance to ensure the durability of your TrawlEye and reduce repair costs. The kit consists of grease compound and foam tips for keeping connectors clean and lubricated. It also includes new support rings for the TrawlEye battery to enforce the O-ring’s sealing. The increased pressure from the support ring makes the lubrication even more important. Molycote S-1002 must be bought from a local dealer due to transportation restrictions.

The grease compound and foam tips will be available as supplies after the first kit.

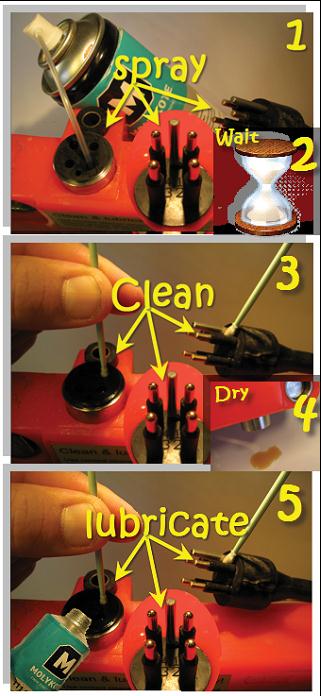

Weekly maintenance procedure:

1. Use Molycote S-1002* electrical contact cleaner with tube installed and spray the cleaner on the connectors (TrawlEye battery and charger). Fill the holes completely in the battery connector.

2. Allow to soak for 1-2 minutes.

3. Manually scrub the contacts with the foam tip and remove contaminants and dirty silicone. Do not use Q-tips (cotton swab)! Using Q-tips may result in small cotton fibers inside the connectors, which will lead to leakage and corrosion.

4. Shake/drip out remaining fluid and allow to drying. Use compressed air if available. Inspect the connectors. If not clean, repeat step 1 to 4.

5. Lubricate with Molycote 111 Compound. Use a clean foam tip to apply a thin layer into the holes and on the pins (battery, TrawlEye and charger).